Our paper making felt include

Single -layer BOM paper making felt

Double -layer BOM paper making felt

Triple-layer BOM paper making felt

Mark-free paper making felt

Full chemical fibre needled paper making felt

Pulp-making felt

Dryer felt

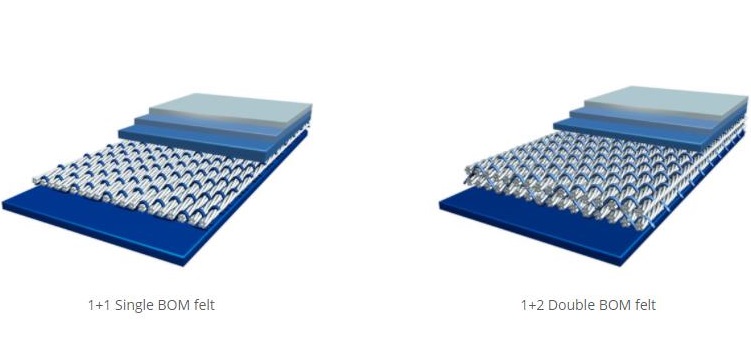

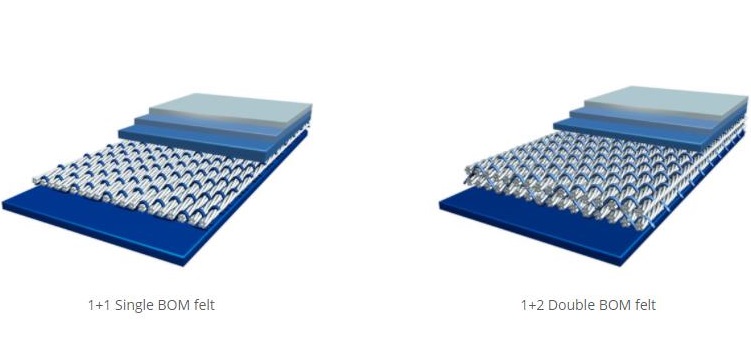

1.Single layer and double layer BOM felt

BOM paper-making felt is composed of the mesh layer and the fiber layer. The classification of BOM felt is usually based on the mesh. The single-layer mesh paper-making felt is a single-layer BOM felt, and the double-layer mesh paper-making felt is a double-layer BOM felt.

This series of felts are usually suitable for medium and low speed paper machines, working speed is less than 800m / min, mainly used to produce packaging paper, culture paper, tissue paper and special paper, etc. the weight range of felt is 700-1200gsm, with the characteristics of flat surface, good compression resistance, strong strength, good dehydration, easy cleaning, long service life, etc.

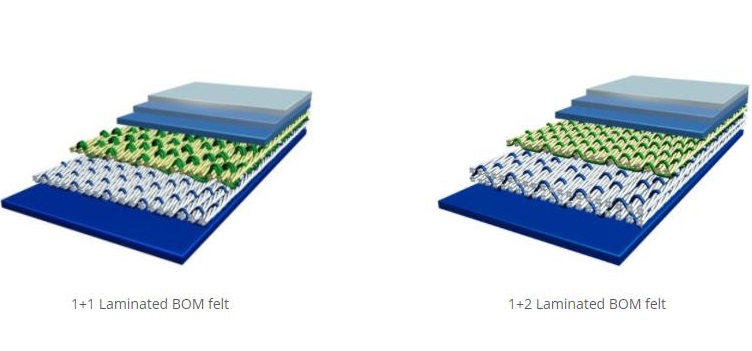

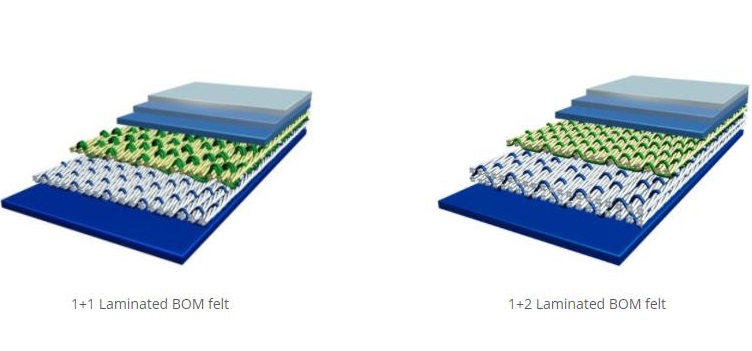

2.Laminated BOM felt

Laminated BOM felt is usually divided into 1+1, 1+2、1+1+1, and other types of mesh structure. The structure of mesh and mesh can be the same or different, and the combination and matching forms are flexible, which can meet the requirements of vacuum press, composite press, jumbo press, shoe press and other press types, suitable to produce packaging paper, cultural 0-1000mpm, and the weight range is 1200-1900gsm. The utility model has the advantages of stable structure, superior compressive performance, strong continuous dehydration ability, large strength, flat felt surface, not easy to deform, long service life, etc.

Stainless Steel Mesh Cylinder ...

Stainless Steel Mesh Cylinder ... Polyester endless sythetic mes...

Polyester endless sythetic mes...